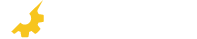

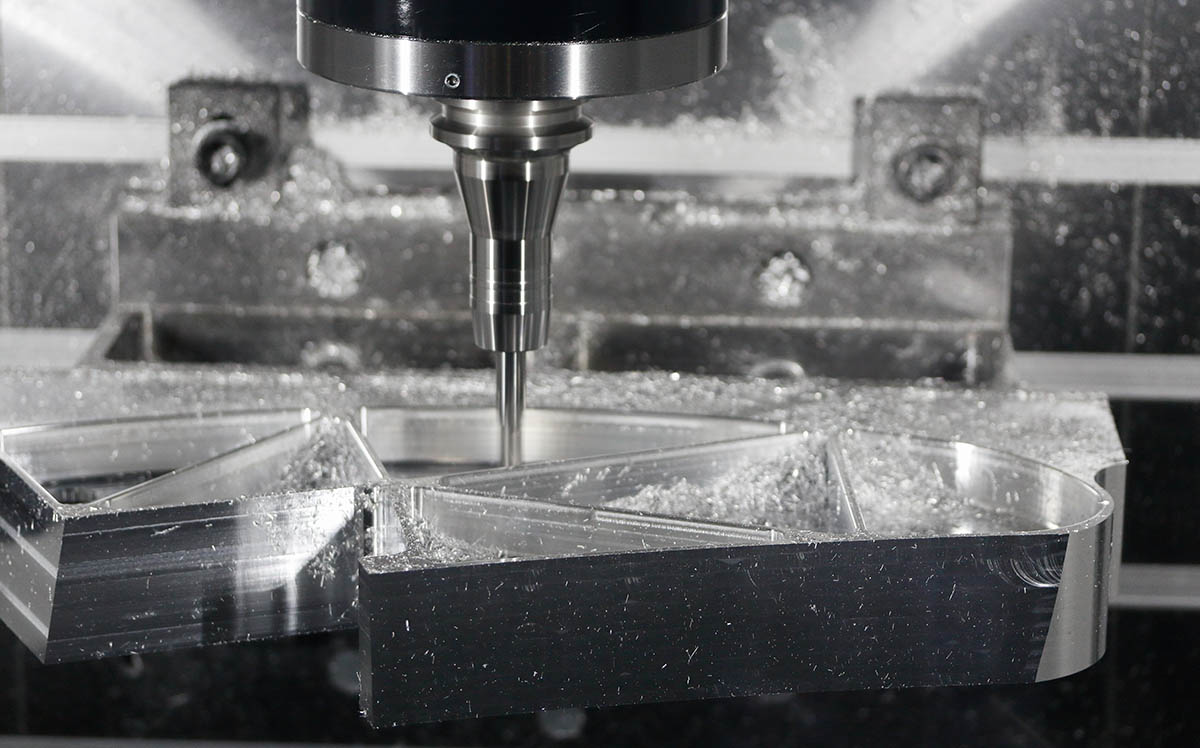

Fiber laser cutting is the fastest way to cut thin metal sheets. It is a modern metal processing process. The main factor in this process is the focused laser beam in the presence of technical gas (Nitrogen or Oxygen). It is a technology that allows you to quickly cut any shapes while maintaining very high precision, guaranteeing 100% repeatability. Thanks to the proper arrangement of details on the sheet, we minimize waste, and the final product has smooth and optimally clean edges.

We offer fiber optic laser cutting services. Our laser allows for quick, very precise and repeatable cutting of elements from all types of sheets.

It can be used for fast and reliable cutting of aluminum, brass, copper and foil-coated stainless steel. Fiber laser technology is used to productively process thin stainless and structural steels.

The maximum sheet size to be processed is 3000 x 1500 mm.

The price of FIBER laser cutting is influenced by the cutting time and the type of material - in order to determine the costs, please send the files in DWG, DXF, STP or PDF format to our e-mail address (biuro@laserpolak.pl)biuro@laserpolak.plfiles in DWG, DXF, STP or pdf format.